Tillage Equipment Comparison: The VRT2530 Versus Angled Coulters

You have probably seen other tillage tools that use angled coulter blades (flat blades with no concavity). Many of these products were different takes on vertical tillage — an attempt to achieve vertical tillage performance while blackening up the soil a bit more.

Some of these implements have coulter gangs at fixed angles. Some have manually adjustable angles, and others even allow the operator to hydraulically adjust the coulter gang angles on the go. As these tools became more popular, many of our customers suggested that we develop our own tillage equipment with angled coulters. Instead, we came up with a completely different concept to address their needs in a better way. The end result is the VRT2530.

The Problem With Angled Coulters

Coulter blades are designed to work at a zero degree angle, in line with the direction of travel. They work great for cutting residue and slicing through the soil to fracture compacted layers. But you run into problems when running them at an angle.

Think of a traditional disk harrow. The blades are concave, or bowled, which is a specialized design to scoop the soil (like a shovel). Then, imagine a flat blade running at an angle. It’s going to scrape along the surface more and cause excessive soil smearing and layering, ultimately resulting in hardpan. Coulter blades running at an angle also have a tendency to clog with mud in wet or sticky conditions as they do not have the natural ability to move soil like a concave disk blade. Additionally, angled coulter blades experience a lot of side pressure, which places increased stress on the bearings, while wearing the blades down quickly. As a result, a lot of farmers who run angled coulter blades often experience higher maintenance needs with these pieces of tillage equipment.

What the VRT2530 Does Better

Rather than running coulter blades at an angle for soil movement, we use shallow disk blades mounted at a 12-degree angle on the front of the VRT2530. These blades are specially engineered to scoop dirt, while keeping soil movement as vertical as possible. At a regular setting, they mix more soil than true vertical tillage tools, but less soil than traditional disk harrows.

Rather than running coulter blades at an angle for soil movement, we use shallow disk blades mounted at a 12-degree angle on the front of the VRT2530. These blades are specially engineered to scoop dirt, while keeping soil movement as vertical as possible. At a regular setting, they mix more soil than true vertical tillage tools, but less soil than traditional disk harrows.

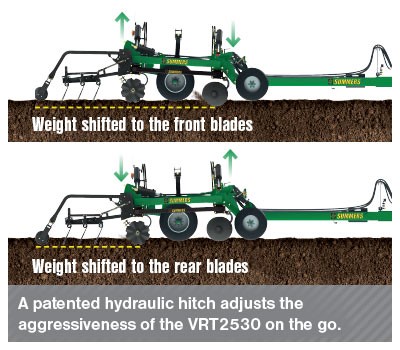

For people who want the ability to move more or less soil as field conditions require, we gave the VRT2530 a patented hydraulic hitch, allowing operators to adjust tillage aggressiveness on the go; hence, the letters “VRT” for variable rate tillage.

By adjusting the hydraulic hitch to dig in the front blades more, the implement will move more soil to help bury heavy residue. By putting less pressure on the front, they will dig shallower to leave more residue on the surface, helping to conserve moisture and prevent erosion when needed.  On the rear of the VRT2530, we use a row of coulter blades fixed at a zero-degree angle for proper field finish. These blades slice remaining residue, while scoring the soil to fracture any layers that may have been created with the front disk blades or previously used implements in the field. When the hydraulic hitch is adjusted more toward these rear blades, you’ll experience performance similar to a true vertical tillage tool, like our Supercoulter, with more residue left on the surface.

On the rear of the VRT2530, we use a row of coulter blades fixed at a zero-degree angle for proper field finish. These blades slice remaining residue, while scoring the soil to fracture any layers that may have been created with the front disk blades or previously used implements in the field. When the hydraulic hitch is adjusted more toward these rear blades, you’ll experience performance similar to a true vertical tillage tool, like our Supercoulter, with more residue left on the surface.

Our extensive testing has proven the VRT2530 to be an excellent alternative to tillage tools with angled coulters — even those with hydraulic gang adjustment. Not only does our solution stay true to engineering principles, but it also takes better care of the soil. If you’d like to learn how this type of tool can fit into your operation, please call us at 1-800-732-4392 or visit your local Summers dealer.

Hats, Diecast Models, Gloves and More!

Hats, Diecast Models, Gloves and More!

Library

Library