The Spray Fill Xpress Greatly Decreases Fill Times, Increase Productivity

There’s a saying that the more things change, the more they stay the same. Farming certainly holds to that. When progress is made, it’s usually incremental. Rarely does something so groundbreaking come along that it completely changes a farmer’s approach.

Take sprayers, for instance. Pull-behind and self-propelled sprayers have helped increase yields and are commonplace on farms across the world. Yet, although technological advancements may make sprayers bigger, faster or more precise, they’re still limited by a simple drawback: It takes valuable time to fill them. As tanks get bigger, these fill times take longer.

Realizing this drawback, Summers invented the Spray Fill Xpress. Now the one limiting factor of sprayers, the amount of time it takes to fill them, has been marginalized to a point of almost being a non-factor.

Numbers Don't Lie

Fill times can vary depending upon different aspects, but for the sake of argument let’s say it takes about 30 minutes to conventionally top off a 1,200-gallon sprayer. If that sprayer is applying 15 gallons per acre with a ground speed of 16 miles per hour, it’ll cover about 1,140 acres in a day, but must stop to refill 14 times. For most farmers, that’s a pretty productive 12-hour shift.  Now let’s add the Spray Fill Xpress into the equation. Recall that it took about 30 minutes to fill the sprayer with the conventional method, so that would result in about 7 hours total of downtime for the 14 refills. The Spray Fill Xpress can slash fill times down from 30 minutes to roughly 7 minutes. With that in mind, the same sprayer putting down the same amount of liquid at the same speed can get in 26 spray/fill cycles in the same 12-hour day, which covers just over 2,000 acres. That’s 932 acres more than conventional filling — an efficiency increase of 82 percent.

Now let’s add the Spray Fill Xpress into the equation. Recall that it took about 30 minutes to fill the sprayer with the conventional method, so that would result in about 7 hours total of downtime for the 14 refills. The Spray Fill Xpress can slash fill times down from 30 minutes to roughly 7 minutes. With that in mind, the same sprayer putting down the same amount of liquid at the same speed can get in 26 spray/fill cycles in the same 12-hour day, which covers just over 2,000 acres. That’s 932 acres more than conventional filling — an efficiency increase of 82 percent.

Feature-Packed Product

The secret to all that filling speed lies in the innovative design and application built into the Spray Fill Xpress.  It begins with the unit itself, which is modular and can be customized with 3, 4, 5 or 6 tanks in 40- or 80-gallon capacities, for a totally capacity of up to 240 gallons. These tanks each hold individual chemicals, which are precisely premeasured thanks to available flow meters and scales. They also remain harmlessly separated until added one at a time to the water stream.

It begins with the unit itself, which is modular and can be customized with 3, 4, 5 or 6 tanks in 40- or 80-gallon capacities, for a totally capacity of up to 240 gallons. These tanks each hold individual chemicals, which are precisely premeasured thanks to available flow meters and scales. They also remain harmlessly separated until added one at a time to the water stream.

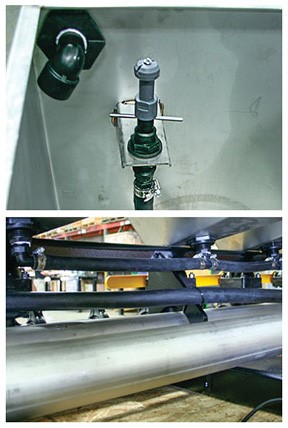

The tanks are stainless steel and deep with aggressively angled walls. This reduces splash back when pouring chemicals, and is integral to moving chemicals quickly into the sprayer.  Each tank also has a handy jug rinse system for convenient cleaning of both jugs and, with the lid closed, the tanks themselves. The attached rinse wand is useful for cleaning, or for making slurry during dry chemical induction. All of the rinse water is easily sent right to the sprayer while filling.

Each tank also has a handy jug rinse system for convenient cleaning of both jugs and, with the lid closed, the tanks themselves. The attached rinse wand is useful for cleaning, or for making slurry during dry chemical induction. All of the rinse water is easily sent right to the sprayer while filling.

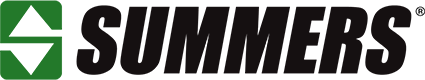

The 3-inch plumbing allows for maximum water flow. When coupled with the available 13-horsepower Honda engine and coordinating 3-inch pump, the water can flow up to 440 gallons per minute.

The benefits of adding a Spray Fill Xpress to a sprayer tending trailer are readily apparent. While the sprayer is in the field, a person on the trailer can premeasure the chemicals into their respective tanks. When the sprayer returns, it’s as easy as connecting it to the Spray Fill Xpress, starting the pump and opening some valves.

Although farming innovations don’t always move the needle a great amount, the innovative technology from Spray Fill Xpress may just make farmers rethink their approach to spraying.

Hats, Diecast Models, Gloves and More!

Hats, Diecast Models, Gloves and More!

Library

Library