When the first DK Diamond Disk was introduced in 1984, it changed the way farmers thought about tillage. Unlike traditional X-frame implements, it didn’t need feathering disks, allowing it to produce clean cuts along field edges and make turns with the disks still in the ground. Additionally, the unique diamond shape helped eliminate the ridging, skipping, gouging and rock damage that are common with other tillage tools. The DK Diamond Disk uses 26-inch concave disks for maximum soil mixing.

DK Diamond Disk

Features & Benefits

- Diamond Technology

- Smooth Disk Blades

- Floating Hitch

- Super-Flex™ C-Shanks and Ductile Cast Spools

- Single-Point Depth Control

- Finishing Coulter Gang

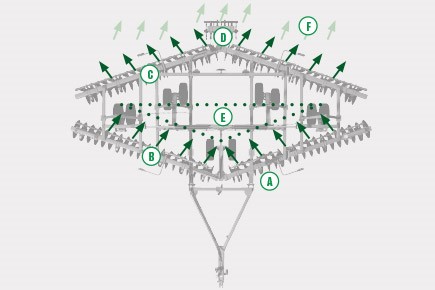

Diamond Technology

A. Diamond shape floats over rocks without damage

B. 19-degree front gang moves soil inward

C. 18-degree rear gang returns soil outward to eliminate ridging without the use of outside feathering disks

D. The rear five-blade finishing coulter sizes residue and levels the soil

E. Triangular wheel arrangement prevents ridging, skipping and gouging

F. Finishing options create the ideal seedbed

Smooth Disk Blades

The DK Diamond Disk uses 26-inch smooth disk blades with 3-3/8-inch concavity for aggressive soil mixing. The blades are mounted on heavy-duty 2-inch shafts and include adjustable mud scrapers that flex with the disk blades.

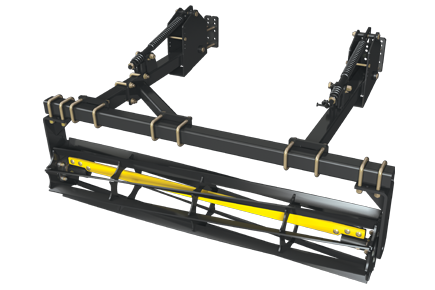

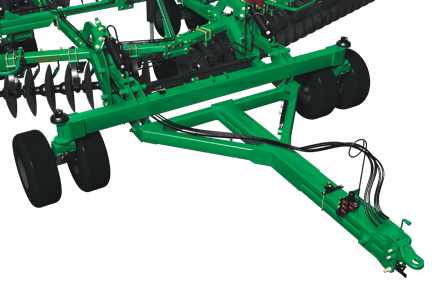

Floating Hitch

Tillage depth is not affected by the tractor wheels, thanks to the floating hitch. Side draft is also practically eliminated because the disk pulls evenly.

Super-Flex™ C-Shanks and Ductile Cast Spools

The Super-Flex™ C-Shanks are an exclusive feature from Summers to absorb shocks and extend the life of the tillage components. To further maximize durability, the toggle-mounted, triple-seal ball bearings are designed to self-align as the gang flexes, and the spools are ductile cast for superior strength.

Single-Point Depth Control

The depth setting for the entire implement can be adjusted from just one of the hydraulic cylinders.

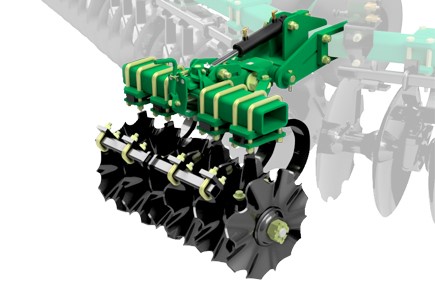

Finishing Coulter Gang

The six-blade finishing coulter gang sizes residue and levels the centerline to provide a uniform soil profile. It uses active hydraulic down pressure for maximum performance.

Options

Mounted Rolling Baskets

Featuring a patent-pending internal mud scraper, the rolling baskets option is ideal for breaking up clumps and providing a uniform soil profile in most conditions.

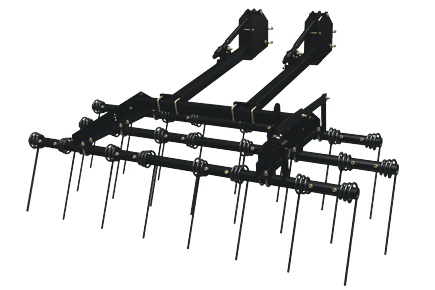

Mounted Harrows

3-bar harrows can be adjusted for deep or shallow penetration. They feature a heavy, yet flexible design for floating over rocks and deep ditches.

Caster Wheels

Dual caster wheels can be added to the floating hitch on DK2610 series Diamond Disks.

Paint Color

With any custom Summers equipment order, choose between green or red, whichever best fits your farming operation.

Specifications

DK9610 (16') Model

Working Width

Transport Width

Total Blades

Blade Spacing

Gang Shaft Diameter

Weight Per Blade

Weight Per Foot

Frame

Floating Hitch Length

Hubs, Center

Tires, Center

Estimated Weight*

Approx. Engine HP*

* Weight and HP requirements without mounted attachments

DK9630 (21'-28.5' narrow center) Model

Working Width

Transport Width

Transport Height

Transport Length

Total Blades

Blade Spacing

Gang Shaft Diameter

Weight Per Blade

Weight Per Foot

Frame

Floating Hitch Length

Hubs, Center

Hubs, Wing

Tires, Center

Tires, Wing

Estimated Weight*

Approx. Engine HP*

* 8-bolt HD optional

** IF320/70R15 optional

*** Weight and HP requirements without mounted attachments