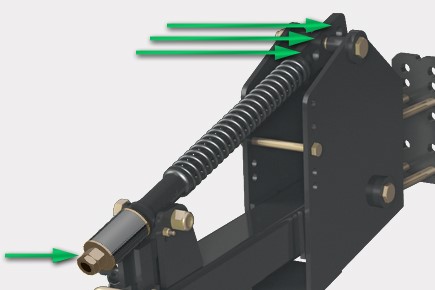

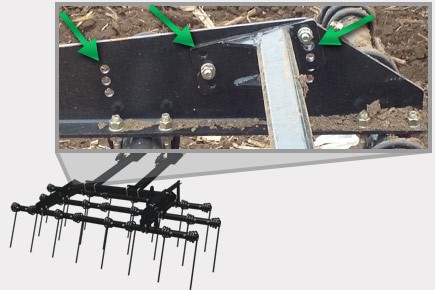

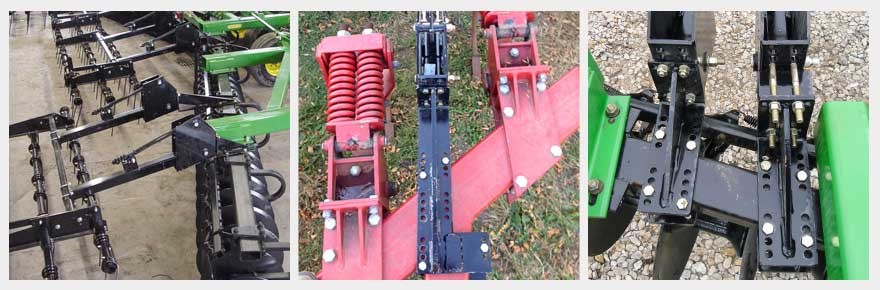

Summers harrows are the toughest in the industry. They offer unmatched performance for distributing residue and leveling the soil in some of the most challenging conditions. Available in 3-bar and 4-bar configurations, the harrows are compatible with a wide variety of implements from Summers, as well as tillage tools from other manufacturers.

Models:

MH1104 – 1/2″ x 20″ tines

MH1105 – 1/2″ x 26″ tines

MH1106 – 9/16″ x 26″ tines

MH1108 – 5/8″ x 28″ tines