The 3RT platform of tillage tools is designed to meet the needs of farmers looking for a maneuverable, compact unit they can simply hook up to a tractor’s three-point hitch. Three configurations (3RT 2010, 2110 and 2210) mean there is a 3RT fit for any rut, reclamation or recreational (spot) tillage application.

The Summers 3RT Platform

Features & Benefits

- Three-Point Hitch

- 3RT 2010

- 3RT 2110 and 2210

- Adjust On The Go

- Adjustable Spacing

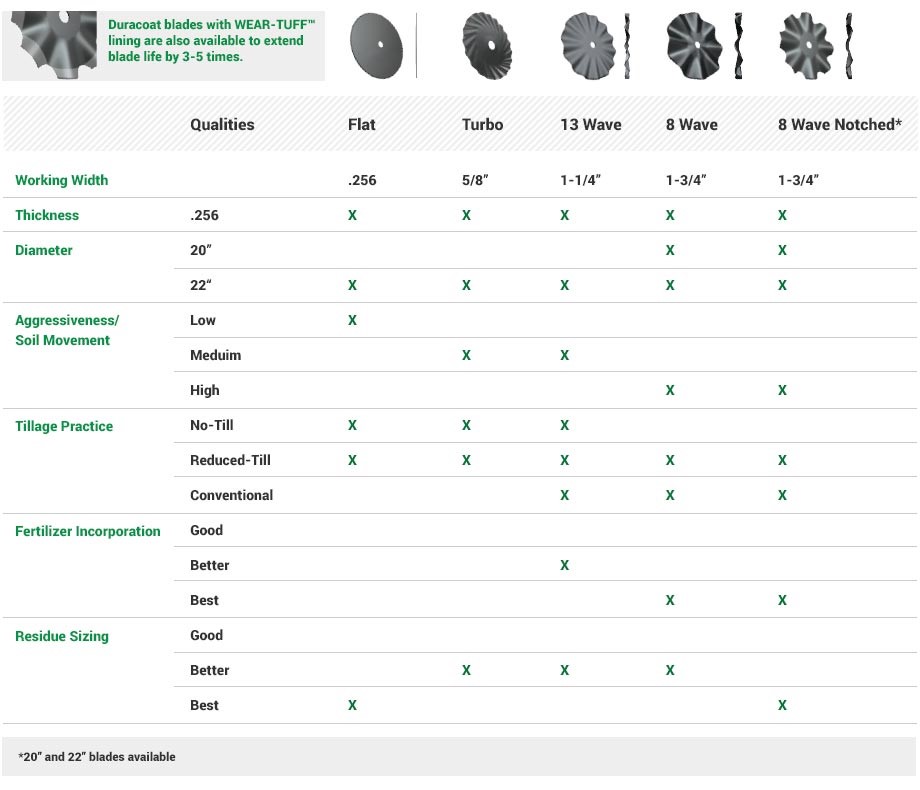

- Coulter Blades

- 22-Inch Dual-Mounted Disk Blades

Three-Point Hitch

All 3RT models easily attach to a tractor’s three-point hitch.

3RT 2010

The 2010 is designed specifically for filling ruts left by heavy farm equipment, such as sprayers or combines. Twenty-two-inch dual-mounted, adjustable angle disk blades bring dirt into the rut, while 22-inch five-blade coulter gangs act as levelers to leave an optimal field finish.

3RT 2110 and 2210

For reclamation and spot tillage, the 3RT 2110 and 2210 are simple, rugged options ideal for working smaller or more confined areas. The 2110 is equipped with a row of concave disk blades for soil mixing, followed by a row of coulter gangs for leveling and residue management. With two rows of concave disk blades, the 2210 is a more aggressive tillage tool that offers increased soil movement and mixing.

Adjust On The Go

Depending on the tractor’s three-point configuration, the operator may have the flexibility to adjust the top link arm and fine-tune aggressiveness as field conditions change. For instance, with the 3RT 2110 this would mean shifting from conventional tillage of the concave disks to vertical tillage of the coulter blades.

Adjustable Spacing

The configuration of the 3RT 2010 is adaptable for 90- to 132-inch-wide center-to-center spacing, so only the intended parts of the field are worked.

Coulter Blades

The 3RT 2010 and 2110 are offered with a variety of blade options to customize your tillage performance. Duracoat blades with WEAR-TUFF™ lining are also available to extend blade life by as much as 3 to 5 times.

22-Inch Dual-Mounted Disk Blades

Disk blades are slightly concave for soil mixing, and manually adjustable from 5- to 24 degrees to customize the soil movement and field finish you desire.

Options

Paint Color

With any custom Summers equipment order, choose between green or red, whichever best fits your farming operation.

Blade Selection Chart

Specifications

2010 Model

Configuration

Working Width

Weight

Transport Width

Overall Depth

Blades Front

Blades Rear

Blade Diameter

Approx. Engine HP

* Adjustable for 90″, 120″, 132″ Wheel spacings.

Adjustable for Category 3 and 4 hitches.

Disk blades are manually adjustable from 5°, 8° and 12°.

2110 Model

Configuration

Working Width

Weight

Transport Width

Overall Depth

Blades Front

Blades Rear

Blade Diameter

Approx. Engine HP

Adjustable for Category 3 and 4 hitches.

Disk blades are manually adjustable from 5°, 8° and 12°.

2210 Model

Configuration

Working Width

Weight

Transport Width

Overall Depth

Blades Front

Blades Rear

Blade Diameter

Approx. Engine HP

Adjustable for Category 3 and 4 hitches.

Disk blades are manually adjustable from 5°, 8° and 12°.

2310 Model

Configuration

Working Width

Weight

Transport Width

Overall Depth

Blades Front

Blades Rear

Blade Diameter

Approx. Engine HP

Adjustable for Category 3 and 4 hitches.

2410 Model

Configuration

Working Width

Weight

Transport Width

Overall Depth

Blades Front

Blades Rear

Blade Diameter

Approx. Engine HP

Adjustable for Category 3 and 4 hitches.

Disk blades are manually adjustable from 1°, 3° and 5°.